Premiere: autonomous/robotic orchard sprayer

Hol Spraying Systems is to reveal an autonomous orchard sprayer that can not only spray, but also refill automatically and take care of mowing, weeding and fertilisation. 10 units are to be in operation in 2022.

Hol Spraying Systems or in short HSS, is a Dutch orchard sprayer manufacturer selling its highly specialised machines in amongst others Belgium, Denmark, Germany, Netherlands, Australia, Canada and New-Zealand. Its sprayers can be equipped with innovative technologies like wind control, variable rate application and chlorophyll sensors detecting foliage (biomass) for optimal coverage. These WEED-IT sensors, developed by Rometron, are also used to determine and record tree shapes and heights and calculate growing power of for instance apple and pear trees.

First robot sprayer in 2016

HSS trailed its first robotic sprayer in 2016 already. At the time, the company cooperated with a Dutch robot manufacturer called Precision Makers. Their Greenbot CR 12 four-wheel robotic carrier was equipped with a single row Cross Flow (CF) 1000 HSS orchard sprayer. Path planning was done by means of teach and playback technology: an operator executes and records the navigation including all operations with a remote control after which the robot follows (plays back) these accordingly.

The pricing was set at € 120,000 for the robot and € 25,000 for the sprayer. Driving in an exact straight line proved to be too challenging for that robot and that made HSS step away from that concept. Meanwhile, Precision Makers ceased to exist.

Hendrik Hol, owner of family company HSS, could not get the idea of an autonomous orchard sprayer out of his head. Shortly after Future Farming revealed the AgBot robot tractor from startup AgXeed, Hol got in touch with them to share his ideas. “I think they have a market ready concept with matching technology and a matching vehicle for my line of business. Their driveline is fully electric which enables optimum control and driving in an exact straight line. They can also control and operate advanced and autonomous spraying technology.”

Wheels instead of tracks

The first tracked version of the AgBot however isn’t suitable for orchards as the tracks disrupt the surface, often grass, while turning on headlands and growers want to keep that grass top layer intact. HSS and AgXeed therefor explored the possibilities of a wheel-driven AgBot. For orchard operations, this will be a tricycle with a single steered wheel at the front with a 710/40 R22.5 tyre and two 400/80 R28 tires at the rear.

Text continues underneath video

According to Hol, a tricycle is ideal in terms of manoeuvrability and also in terms of ground pressure, because each wheel travels in its own track. Thanks to the low centre of gravity, he does not expect any stability issues on slopes.

The mounted CF2000-AB consists of a 2,000 litres (528 gallons) 90 cm wide tank with an integrated 200 litres (52 gallons) rinse tank. The robot’s rear three-point linkage with a lifting capacity of 2.5 metric tons will carry the electrically driven fan, a removable spray boom/tower with 16 air outlets (8 on each side) with nozzle bodies and optionally HSS’s WEED-IT/ISA sensors. Both spray and mixing pumps are hydraulically driven and can’t be demounted from the vehicle.

The AgBot 2.055W3 has a 2.9 litres 4-stroke Deutz Stage 5 diesel engine with 75 hp. Optionally there’s an electrical 68 hp/700 Volt PTO drive and electric 68 pk/700 Volt connectors for electrically driven implements and machines. The 2.8-ton robot also supplies 85 litres hydraulic oil per minute at 210 bar via maximum 3 double acting valves.

Auto refill stations available

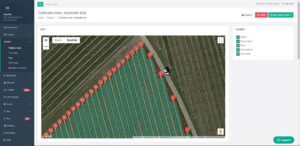

The AgBot finds its way with one GNNS-receiver that requires RTK-accuracy. It is equipped with a LiDAR and an ultrasonic sensor for obstacle detection. HSS uses Belgian Agromanager software that enables growers to record and manage tree positions, AB-lines and start and end point of each operation. These data are sent to the online AgXeed portal where you do your path and operations planning. Application and prescription maps are sent directly from Agromanager to the orchard sprayer.

When spraying, the vehicle drives forward while the digital tank control keeps track of the volume in the tank. HSS plans to offer refilling stations at which the robot can autonomously refill its tank with premixed spraying liquid. The spray tank has an electric valve to enable this.

You have to start the HSS AgBot manually but once it’s done with its spray job, it will automatically rinse the spray lines and tank, park itself at a predefined location and shut down.

To automate other operation too

HSS plans to ‘autonomate’ all crop care operations in orchards with its AgBot solution. Growers can choose to buy an electrically driven rotary mower, mulcher, fertiliser spreader, finger weeder, weed sprayer and root pruner. If needed, machines will be converted to electrically driven.

While mowing and weeding, the robot drives backwards to ensure that after turning on headlands, the implements and machines are aligned properly and straight in between the fruit trees. Another advantage of this mode of operation is that the vehicle doesn’t drive on the grass that is to be mowed. Looking forward, Hendrik Hol expects fruit growers with 50 to 60 ha apple and/or pear orchards to use one robot for spraying and a second unit for spraying and all other operations.

HSS offers the AgBot 2.055W3 robot tractor exclusively to fruit growers across the world from € 135,000. The CF2000-AB sprayer including removable spray boom/tower is priced at € 46,000 or € 64,000 when equipped with six WEED-IT/ISA sensors. A two-tank auto refilling station will be offered for € 26,000 and a four-tank version costs € 30,000.

The European Union and the European Regional Development Fund within the framework of the OPZuid programme contributed to the development of the autonomous platform.

Join 17,000+ subscribers

Subscribe to our newsletter to stay updated about all the need-to-know content in the agricultural sector, two times a week.