Farmdroid promising: users learn a lot (1)

Dutch chicory company Sensus has rolled out the red carpet for the Farmdroid FD20. With a substantial sustainability bonus, the chicory processor supports growers who are experimenting with the field robot. A tour among the early adopters reveals that they are eager to make the alternative weed control approach work, but it does not immediately go smoothly. In the second article we will discuss the experiences of farmers.

“You can compare the acceptance of the Farmdroid to that of a robotic vacuum cleaner,” says Koos Havelaar of Dutch Farmdroid importer HAK Havelaar. “Switching from a traditional vacuum cleaner to a new stick vacuum cleaner is easy. It essentially changes nothing about your method. You can quickly go through your house or room, but a robotic vacuum cleaner is a different story. It takes the work out of your hands at a completely different pace. It’s really a different concept, something new. It requires a different way of looking at the task.” More agriculturally, the comparison with the milking robot comes to mind. Purchasing that also requires a significant change in business operations.

The question was why there are almost a hundred of the Swiss Ecorobotix ARA spot sprayers behind tractors running in the Netherlands, while the count for the Farmdroid in the Netherlands is still at fifteen? Both have only been on the market for a short time and both drastically reduce chemical use. Havelaar: “A big difference in my eyes is that the Ecorobotix does what farmers know. It’s a precision sprayer in the hitch of the tractor. With a driver on it who drives over the land at a normal pace. The Ecorobotix spotsprays with great precision whatever weeds it encounters. No hard feelings about that, but the Farmdroid, which goes completely autonomously over the land at – say 500 meters per hour – is really a completely different approach. It’s a transition and that requires something from the grower. Purchasing such a robot is really something else.”

Text continues below picture

Seeding according to a fixed grid

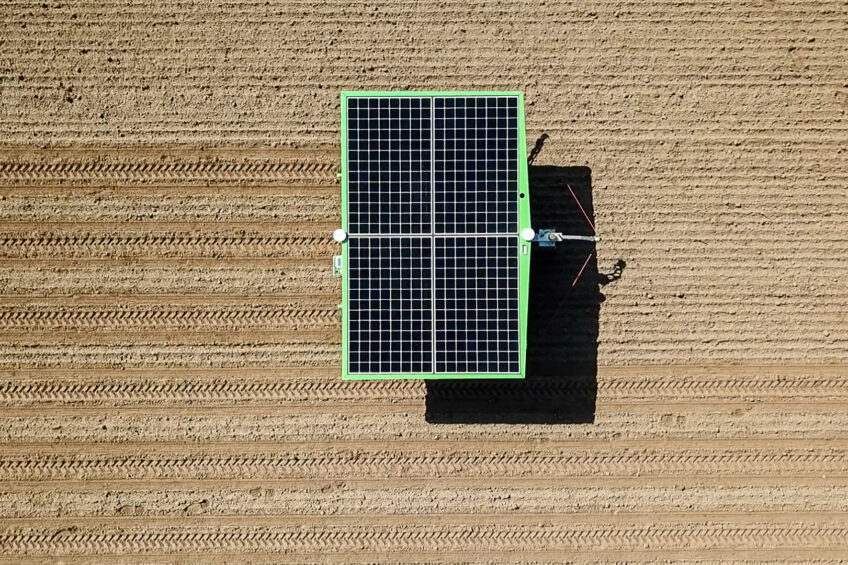

The Farmdroid FD20 is a solar-powered robot tool carrier that can both seed and hoe. The robot is suitable for various fine-seeded crops, such as sugar beets, chicory, onions, spinach, canola, etc. After first measuring all the corner points of a plot – the robot does not drive curves – the robot seeds with great precision according to a pre-programmed fixed grid. The seeding elements precisely place the seeds, and the machine remembers exactly where each seed lies. The machine can be equipped with a spot spray system that sprays a soil herbicide in a patch on the seed. The robot seeds at a low speed, covering about two and a half hectares per day. At Dutch farmer it took six days to cover 16 hectares.

The machine operates entirely electrically. Four solar panels on top charge two batteries. If there is enough sunlight during the day, the work continues at night. If the batteries run out at night and the Farmdroid stops, it will resume work in the morning when there is enough light. Different growers have extra batteries to swap if the machine stalls.

Hoeing before emergence in the row

After seeding, the machine is converted to be able to start hoeing. This means that the seeding elements go up, and the hoes for between the rows are mounted. For hoeing in the row, there are movable arms per row with a small hoe blade attached. This blade folds out between the individual plants to weed there.

We are very interested in what the robot can mean especially for chicory

Since the machine knows exactly where the seed – or clusters of seeds, as with onions – has been placed, hoeing can start before emergence. Especially on larger plots, it is usually necessary to start hoeing right after seeding and then continue, as the tour soon takes about a small week. It’s important to catch the weedlings in the white-thread stage.

Text continues below picture

Experimenting with hoes

In this sense, the changeable weather last spring did not work out well for the Farmdroid. On the one hand, rain stops the machine (it turns itself off at a set amount of rain). On the other hand, after a bit of sharp drying at the surface, a crust forms that makes hoeing difficult. Pushed-aside pieces of hard soil can then damage young crop plants. Therefore, users are experimenting with different hoes than the standard delivered steel rods that go through the soil, such as angle hoes that point inward from the crop row.

Pressure on chemicals helps Farmdroid

The Farmdroid seems at first glance to be a machine that will especially be embraced by organic growers. It is often said that anyone who controls weeds without chemicals can become an organic grower. The in-row hoeing replaces a lot of manual labor, which is expensive and scarce. Yet, most Farmdroids are now on conventional farms. Maybe that makes sense, as there are more of those. But it is indeed the pressure on chemical weed control that plays into the hands of the Farmdroid.

Herbicide approvals are expiring, with no new suitable ones coming in place. Particularly chicory processor Sensus has therefore welcomed the Farmdroid with open arms. Ever since the emergence of the chicory crop, the cultivation support by this Cosun BV has mainly focused on weed control. Until a chicory crop covers the soil, the slowly growing plants struggle in competition with weeds.

Text continues below picture

Financial support for purchase

“In the fall of 2021, we started looking at what the Farmdroid could mean for chicory,” says René Schunselaar. He is the Agro Manager at Sensus. Through the French importer, we then got a machine that worked in chicory. “We were and are very interested in what the robot can mean for chicory.”

The first experiences with the seeding and hoeing robot FarmDroid in the 2022 season were promising, according to Schunselaar, although there was also “a lot learned.” Through support in 2023, Sensus offered growers the opportunity to largely pre-finance a FarmDroid via the Groeikracht Cosun initiative. In 2023-’24, the use of the Farmdroid FD20 is included in the conditions to qualify for the sustainability bonus in the chicory contracts. This means a bonus of €15 per ton of chicory, or €750 per hectare at a yield of 50 tons.

Text continues below picture

Different from precision hoeing with camera

Schunselaar from Sensus: “All other new hoeing or weeding technology that I know of is based on image recognition of crop and weeds. The contrast of weeds with chicory is small. We have experienced in chicory that image recognition does not always work perfectly. Before chicory is recognized as such, it is, so to speak, already overgrown by weeds. The plants also stand close together in the row, 9 to 10 centimeters. If chicory is eventually large enough to be recognized, a camera only sees green. That doesn’t work. The precision positioning with which the Farmdroid works is different from other precision techniques.”

This spring, the Farmdroid requires a lot of attention. Still too many malfunctions

As mentioned, the counter of sold Farmdroids this spring stands at fifteen. Eleven of them run in chicory. A total of 500 have been built and sold in Denmark up to this spring, reason for the manufacturer to bring out a Limited Black Edition.

No plug-and-play

Using a field robot is not just that the grower has to switch a button in his head, as importer Koos Havelaar tells. There are still concrete issues that require first looking at the cat from the tree. The use of the Farmdroid is not simply a matter of charging the battery, putting the machine in the field, and pressing the on button. With this innovation, it’s not a matter of plug-and-play. Users say they appreciate the machines, see perspective in them for their businesses, but at the same time list a series of bumps on the road to flawless operation.

Join 17,000+ subscribers

Subscribe to our newsletter to stay updated about all the need-to-know content in the agricultural sector, two times a week.