WeLaser technology on display at Dutch Precision Days

An international group of companies and researchers is working on a machine to control weeds using fiber laser technology. During the Precision Days at Van den Borne in The Netherlands on August 25 and 26, the machine was on display in the Netherlands for the first time.

As a visitor to the Precision Days at Van den Borne Potatoes in The Netherlands, you would simply pass by the WeLaser demonstration without an explanation or specific interest. The orange-colored autonomous CEOL robot vehicle from Agreenculture with a so-called white box behind it was hidden behind a tent. The laser technology from WeLaser was contained in that white box.

WeLaser is a European funded project that develops a weed control system based on high power laser technology. Van den Borne is one of the project participants, which is why the current prototype of the machine was on display in the Netherlands for the first time on 25 and 26 August.

Text continues below picture

Fiber laser like laser cutter

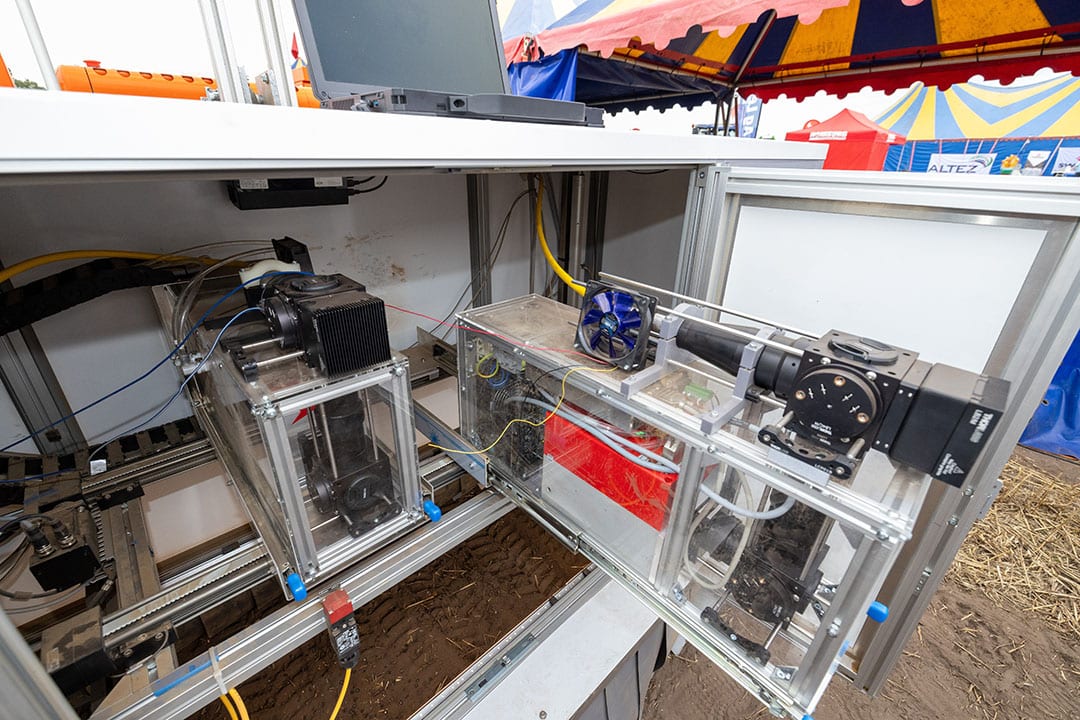

To date, laser technology for weed control has opted for blue lasers and CO2 lasers. However, WeLaser opts for so-called thulium fiber lasers. Fiber lasers are used for laser cutting plastics and metals and, according to the researchers, have the advantage of a high-quality light beam.

Unlike a CO2 laser, a fiber laser also has no internal mirrors and the technology is faster thanks to the use of fiber optic cables. These cables transport the light needed for the 3 mm thick laser beam produced by LED lamps. Because fiber lasers are more energy efficient, less energy is also needed, according to the researchers. Each used 2 μm laser requires 250 watts.

Text continues below picture

Cooking weeds

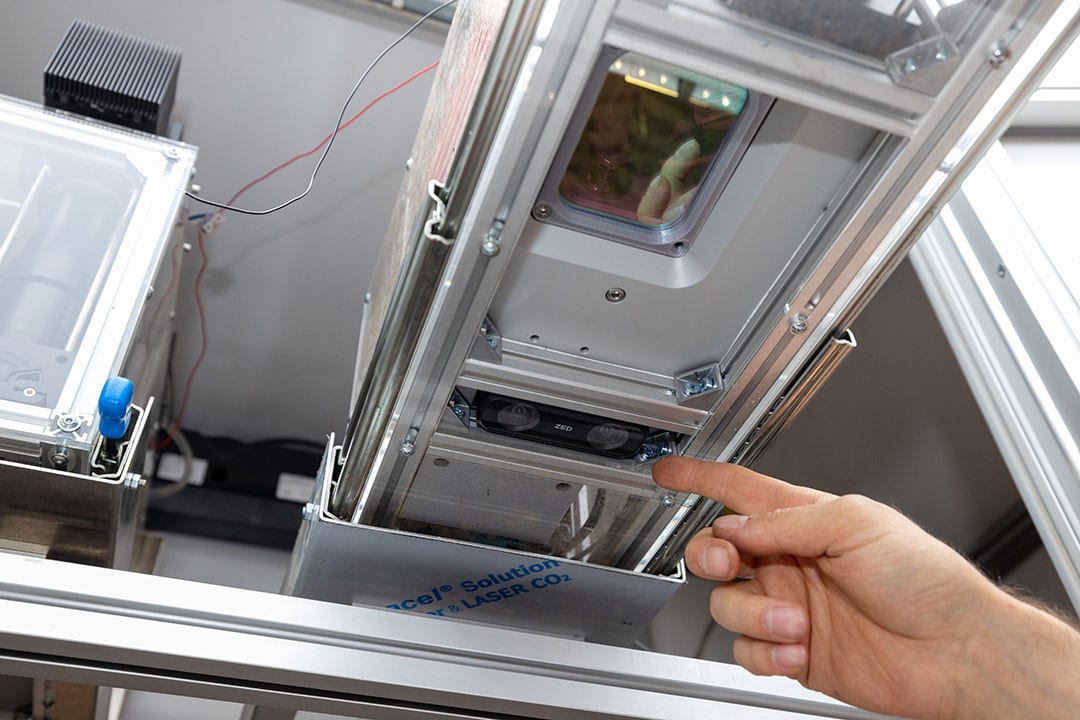

For navigation, the Agreenculture CEOL is equipped with an RGB camera for driving tracking at the front. There was no crop during the demonstration, so a route was created in advance in the online planning tool. The vehicle followed that route using RTK GPS. The current version features two sets of 3D ZED X stereo cameras and fiber lasers. The cameras locate weeds and cultivated plants.

There is an algorithm for working in corn and sugar beets. The algorithm recognizes and labels corn/sugar beets, grasses and other weeds. The lasers then aim their laser beam at the growth point of the weed to cook it by heating it. The fact that a typical plume of smoke is created is a special effect of the researchers to show that something is happening.

Text continues below picture

Up to 0.9 meters per second

The maximum weed size is 2 to 3 centimeters (up to 4 leaves) and the current driving speed is 0.2 to 0.9 meters per second. 1 meter per second equals 3.6 km/h. As soon as weeds are moist, it takes longer to control them and that also costs more energy.