The great potential of spot specific tillage (and why it hasn’t been unlocked yet)

Many farmers and growers now routinely target and adjust seed rates and fertiliser applications to match specific soil and crop requirements. But these crops are growing in seedbeds that, most probably, have been cultivated to a uniform depth.

Few farmers would not dream of varying inputs without first using detailed soil maps and sampling to investigate variances. But, when it comes to cultivations, they continue to treat the field as if the soil is all the same.

Compaction

“I am in no doubt many soils are now being worked too deeply and are suffering from being over-cultivated,” comments Philip Wright, an independent soils specialist in the UK. “There is a real danger that cultivation operations at the wrong depth, will be doing more harm than good. If, for example, you are trying to alleviate compaction, unnecessary cultivations may over-loosen the soil and that, unfortunately, has the opposite effect and makes it more vulnerable to compaction.”

It is vital to establish the actual depth of the compaction or hard layer and ensure the loosening tine is set just below this critical depth. Any deeper and it can compact the soil upwards, as opposed to lifting and shattering. This will consume more power and the extra effort will all be wasted, because the potentially smeared land at depth simply presents a greater barrier to root growth and the passage of water – more compaction.

You seldom need to treat the whole field with a subsoiler or other loosing tine machines

“Also remember that you seldom need to treat the whole field with a subsoiler or other loosing tine machines. And they don’t necessarily need to work at the same depth,” he adds. “Recently, in my own trials in the UK, I have noticed that hard layers can be now much shallower than before.”

“This is thanks to more attention to soil structure, less random trafficking, keeping to tramlines and better tyre technology. We often find the soil that needs loosening is now sometimes only 12cm to 15cm deep – it’s not down at 30cm or even 40cm, like it was in the past.”

Text continues underneath image

Dig down to the problem

First step on the road to variable depth cultivations is made in the field – with a spade in your hands, comments Philip. “You not only need to know where the problems lie, but at also at what depth. Use soil maps, your own experience and obvious signs on the ground to find likely problems and, before doing anything, you should dig a hole and investigate the problem and it’s depth,” he explains.

Time spent digging and investigating is seldom wasted. “It’s unlikely the whole field needs remedial treatment to remove compaction. So just targeting specific areas will save time, diesel and money,” he adds.

Text continues underneath image

Varying depths in real time

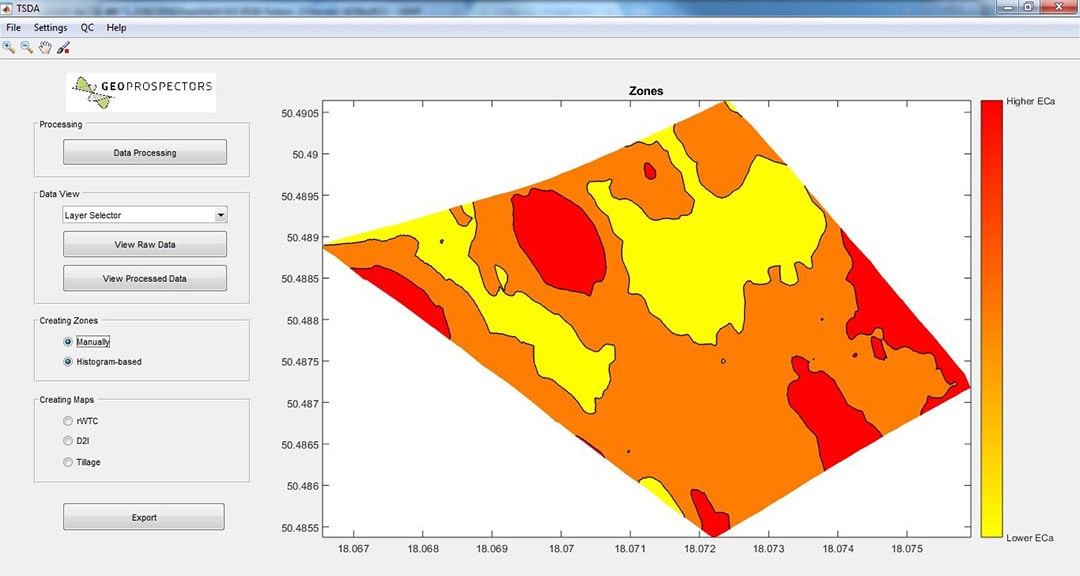

Electrical Conductivity (EC) scanning is now an increasingly popular way to assess the state of soils to create maps of types and textures. Essentially EC measures how easily electricity passes through the soil, with the response related to its composition – moisture content, texture, sand, clay and organic matter.

The resulting map is then used to identify difference soil textures, which are often grouped together to create zones for variable rate applications. These can also be used for variable depth tillage.

At the Agritechnica show in 2015, an Austrian firm, Geoprospectors, won a Silver Medal for its non-contact Topsoil Mapper Sensor (TSM). This contactless EC sensor measures soil conductivity at four different depths – 0-25cm, 15-60cm, 55-95cm, 85-115cm.

Designed for mounting on a tractor’s front linkage it can be used in two ways:

- Mapping fields, to record texture variances and to create soil type maps and relative water content maps

- Determine the presence and depth of compacted areas, to enable variable depth soil cultivation to be carried out with compatible equipment.

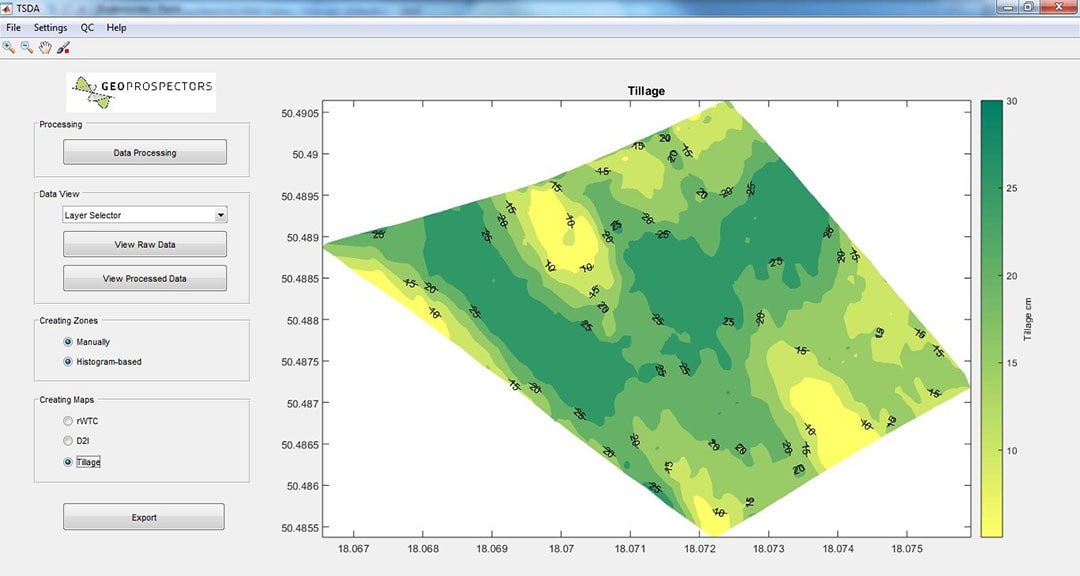

Now, with ISObus compatibility, the system can not only detect the variances or compaction depths, but also automatically adjust a compatible cultivator’s tine depth, in real time while at work in the field. At the same time it maps the soil types and treatments, for further operations.

Text continues underneath image

Site specific tillage

Site specific tillage using the real time and varying cultivation depths to suit the soil, can offer considerable benefits. The TSM system allows operators to choose three different tillage strategies:

- Subsoiling – for deep loosening it detects and eradicates any compacted areas, without treating the entire field unnecessarily

- Shallow cultivation – for operating at shallower depths in clay type soils or reducing erosion by leaving residues on the surface

- Depth contour – provides layered tillage to avoid breaking up compacted layers and mixing subsoil with topsoil.

While soils expert, Philip Wright, encourages the use variable depth cultivations, he says to get the best from fully automated systems he encourages users to still ‘ground proof’ the results.

“I suggest using the sensor in mapping mode over certain areas, which you probably know about anyway. Then use the maps to determine dig to investigate the true level of compaction and its actual depth. You can also use this information to set upper and lower parameters for the automated operation. It won’t take too long, but could bring further benefits,” he explains.

Text continues underneath image

Cultivation cost cuts

Cultivating to precisely the correct depth and only where necessary protects the soil from damage and results in significant cost savings.

Last year Soyl, a crop production service provider in the UK, demonstrated the TSM working a cultivator at variable depths with ISObus control on a John Deere 7830. This also had the sensor integrated into the front weight, allowing the system to be used during cultivations when ballast is required, while protecting the sensor at the same time.

Research by Soyl, shows the average UK tillage depth is about 20cm and will consume about 14.1 litre/ha in diesel. Writing last year, Ed Jones, Soyl and sustainability knowledge exchange manager, says if tines go down to 40cm fuel use rises to 26.4 litre/ha.

At a diesel price of 60p/litre this equates to £8.46/ha at 20cm, which rises to £15.84/ha at 40cm. Research shows variable depth tillage, he adds, indicates an economic benefit of 27% to 50%, compared with conventional cultivations.