John Deere HarvestLab 3000 available on combines for analysis of grain and rapeseed

John Deere HarvestLab 3000 is now available on the S and T-Series combines, expanding the use of near-infrared sensor to four applications by enabling constituent analysis for grain and rapeseed.

John Deere HarvestLab 3000 is known from self-propelled forage harvesters, stationary usage and manure sensing. Now it is an option on combine harvesters, called Grain Sensing.

Quality parameters in wheat, barley and rapeseed

John Deere says this helps to measure important quality parameters in wheat, barley and rapeseed in real time and continuously. In addition to moisture, the protein content of wheat, barley and rapeseed can now be determined. Furthermore, the starch content of barley and the oil content of rapeseed can be recorded.

Farmers receive sitespecific information on the harvest quality of individual fields, which enables them to:

- Know for certain whether the wheat is of milling or feed quality. This allows batches to be stored separately according to quality and marketed in a more targeted way.

- Better documentation of the harvest as the grain quality is recorded at each individual point in the field.

- Compare varieties or validate their machine settings.

- An overview of which areas of the field have successfully converted nutrients (e.g. nitrogen) into yield and protein/oil, so they can better plan fertiliser application for the next season.

Grain Sensing

Grain Sensing is a fully integrated solution that is mounted on the clean grain elevator. The following components are required for use on the combine:

- HarvestLab 3000 near-infrared sensor

- Field-kit to install the sensor and the necessary hardware

- Grain sensing calibration

- Gen 4 display

- The JDLink agricultural management system solution

- StarFire receiver

Grains pass in front of John Deere HarvestLab 3000

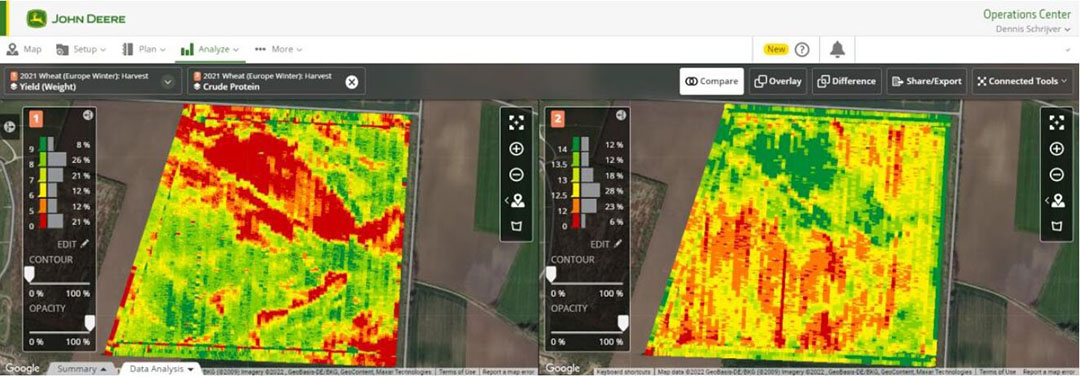

Before the grains enter the grain tank, they pass directly in front of the John Deere HarvestLab 3000 with the help of a motor-driven auger. Together with the StarFire receiver, site-specific data can be generated on the Gen 4 display, which can automatically synchronise with the John Deere Operations Centre via JDLink TM. Here, harvest results can be reviewed with features such as Analyze and Field Analyzer.

It is also possible to connect the Operations Center with partner softwares to gain further insight or create application maps for future input operations.

John Deere says the HarvestLab measurement supports farmers in future cultivation and input planning. The solution helps to gain an overview of the amount of nutrients (especially N) extracted during the harvest. This can then be used to calculate the nutrient efficiency of each field zone.

Text continues below image

The HarvestLab will be available on T-Series (Retrofittable from Model Year 2016 or newer) and S-Series (Retrofittable to all S760, S770, S780, S785 and S790) models from spring 2023 to be ready for next harvesting season.

Join 17,000+ subscribers

Subscribe to our newsletter to stay updated about all the need-to-know content in the agricultural sector, two times a week.