How crustaceans could optimise crop fertilisation

Brazilian researchers are developing natural and biodegradable polymers for the coating of nutrients to obtain enhanced efficiency fertiliser (EEF). Chitosan, made from crustaceans, appears to be a particularly suitable material.

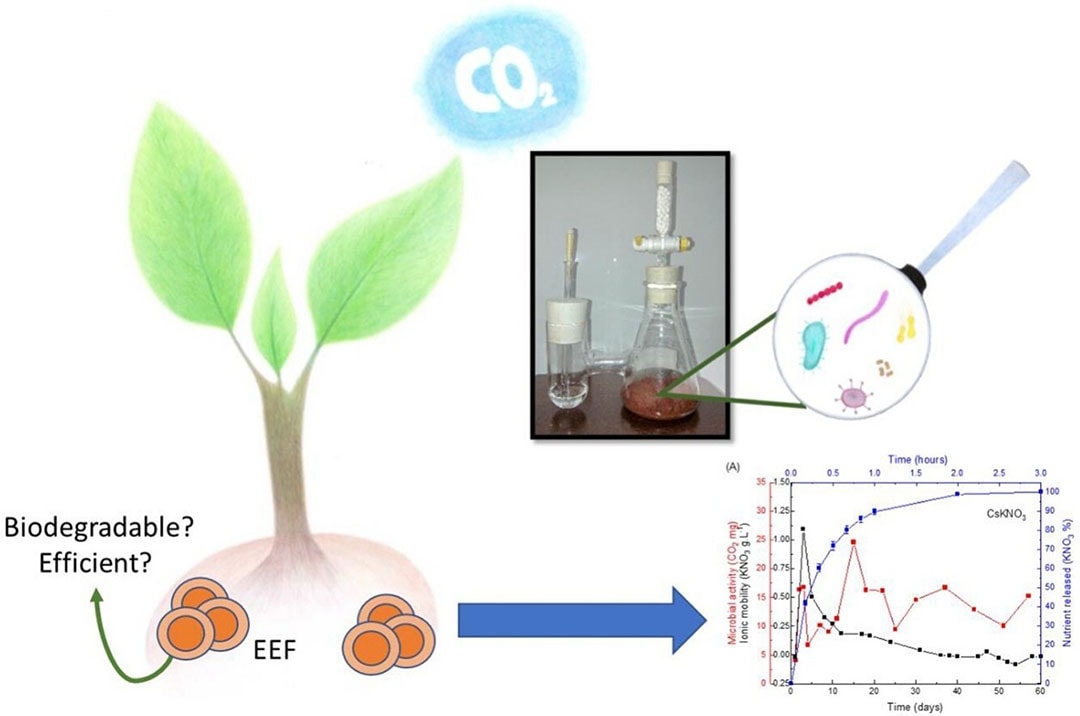

The coating of nutrients to obtain enhanced efficiency fertiliser (EEF) is a common practice in agriculture. The material used as a matrix to coat or carry nutrients on the EEFs must be nutrient compatible, control the release, degrade after use, and be harmless to the environment.

Researchers from the Federal University of São Carlos (UFSCar), in Brazil, are developing natural and biodegradable coatings that can encapsulate nutrients and guarantee a controlled and gradual release of fertiliser.

The research has been conducted since 2014 and was supported by FAPESP (Fund for Research Support of São Paulo). Results were recently published in the article ”Biodegradation and viability of chitosan-based microencapsulated fertilizers”.

Less money and waste

Roselena Faez, coordinator of the study, said that fertilisers contain very soluble salts, easily released by rain. “Due to this, encapsulation allows them to be released in a controlled and gradual pace, reducing the amount of fertiliser a grower needs to apply. This saves a farmer money and reduces waste”, Faez said.

According to the researcher, solving the encapsulation issue is an essential step towards making so-called enhanced efficiency fertilizers (EEFs) possible. Matters of importance here are the ability to release nutrients, the absorption of fertiliser by the crop, biodegradability of the coating material and cost-effectiveness of the product.

Chitosan

“To create an appropriate material for the coating, we started with chitosan, a bio-based polymer, which is abundant, renewable and easy to obtain”, Faez said. Chitosan is made from chitin, a polysaccharide present in crustacean exoskeletons – such as shrimp, lobsters and crabs – and in the coatings of insects and fungal mycelia. “Chitosan has very good mechanical properties, combined with the ability to form gels, fibers, films and microspheres, which enable the most diverse applications. It is extremely attractive due to its biocompatibility, biodegradability and non-toxicity”, Faez said.

Text continues below image

Microspheres and microcapsules to coat fertilisers

Based on chitosan, Faez and her collaborators prepared microspheres and microcapsules to coat fertilisers. Results show the process of releasing the nutrients relates to both the diffusional process – water entering and nutrients exiting – and capsule biodegradation.

Currently, the researchers are aiming to understand effects, type and quantity of different nutrients in the biodegradation process. “We are working with essential macronutrients (potassium, nitrogen and phosphorus) and also micronutrients (copper, manganese, iron, etc.), in order to evaluate the soil microbiological system during and after the polymer biodegradation”, Faez said.

The researchers also published a review of advances over 20 years on polysaccharide-based polymers applied as enhanced efficiency fertilisers.