Savings on resources by spot spraying broad-leaved dock

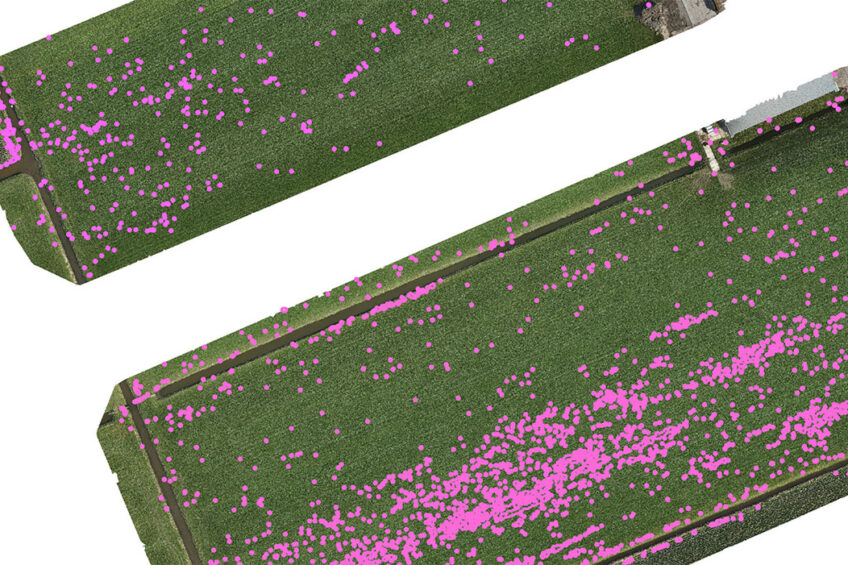

After a few years of testing on a smaller scale, Dutch bulb grower Stef Ruiter in Andijk (The Netherlands) is going into practice this season with a site-specific approach to broad-leaved dock (Rumex obtusifolius) in grassland at dairy farmers, with whom he collaborates for tulip cultivation. In short, it comes down to first mapping the sorrel with the help of a drone, after which they are sprayed in spots with the field sprayer.

Compared to full-field spraying, a site-specific approach has several advantages: more than 90% savings on weed killer, nitrogen binder clover is spared and no growth stagnation of the grass where spraying is not done. Compared to manual spot spraying with the backpack sprayer, working with a task card and field sprayers gives enormous labor savings, which also increases accuracy, fewer missed sorrel plants.

Dairy farmer Auke van Zanten in Andijk cannot precisely quantify the degree of growth stagnation, but says that the grass gets ‘a considerable blow’ from full-field spraying.

Sorrel is a troublesome root weed, in the sense that it can become a persistent problem if not controlled properly. Sorrel competes with grass and the oilseeds pass unscathed through the ensiling process and the gastrointestinal tract of the cow when the seed is harvested. With the spreading of the manure, the next generation of sorrel is in fact sown again. And specifically for bulb growers, sorrel is difficult, because they grow through the nets and then cause a problem with the harvesting.

Less chemistry is in line with government ambitions

That is why it is important that sorrel is constantly suppressed. Not only for good grass cultivation, but also for bulb cultivation. Ruiter strives to minimize the use of chemical agents, including herbicides. The current practice is that in the case of a slight infestation of a plot, the sorrel is controlled by hand. With a heavy occupation, the weeds are controlled full field with the sprayer.

A low occupation of a plot with sorrel means that it does not have to be sprayed to death prior to bulb cultivation. “We can then immediately mulch it, crush the top layer shallowly with the cultivator. This feeds the soil and stimulates soil life. Towards a more regenerative agricultural system.”

In collaboration with dairy farmers, Ruiter-Wever maintains a crop rotation with tulip bulbs grown on average once every eight years. Sometimes also a vegetable crop in between.

Text continues below picture

Mulching grassland without first spraying it to death with glyphosate fits in with the wish of agriculture minister Piet Adema to use alternatives to spraying grassland, green manures and catch crops in anticipation of an obligation. Alternatives would become mandatory by 2025 at the latest, he wrote to the House of Representatives in mid-April. Adema invites the dairy farming, arable farming and flower bulb sectors to come up with alternatives for spraying grassland to death.

Text continues below picture

Marking accurate to 4 centimeters

Ruiter has the plot scans carried out by the ABDrone company of Leks Bolderdijk in Stadskanaal. ABDrone takes about 150 photos per hectare with a drone from a height of 40 meters, and has these photos combined via image stitching (sewing together) into one image of the entire plot in high resolution. In it, the sorrel plants (or other plants if desired) are detected by a computer algorithm, which in turn forms the basis for the task map that Ruiter receives 3 to 4 days after the drone flight.

Text continues below video

Central role for contractor

Stef Ruiter is now starting spot spraying at the growers with whom he exchanges land in West Friesland. “But this approach is not necessarily related to bulb cultivation. We happen to already be working here with the dairy farmers and we have the machines. In fact, every dairy farmer in the Netherlands can use it. At least if he has a contractor nearby who has or wants to purchase a sprayer with the option of spot spraying. It would be nice if contractors in a certain area would play a coordinating role; that they will offer site-specific weed control as a service to customers. They could arrange to create the job maps and then do the spraying. The system can be rolled out in no time.”

Join 17,000+ subscribers

Subscribe to our newsletter to stay updated about all the need-to-know content in the agricultural sector, two times a week.