Trimble’s new Path Planning Tech: paving the way to driverless tractors

Trimble has recently introduced Path Planning Technology. In an exclusive interview, Future Farming delves into the benefits and practical gains through 10 insightful questions. Discover how this intelligent path planning technology helps to find the best coverage path so that costs of various field operations can be minimized. The next step in the near future will be to remove the operator from the actual machine.

Can you estimate how many farmers currently use path planning technology? In which regions is adoption particularly high, and what are the reasons behind it?

We are currently field testing the path planning technology at multiple farm sites across three continents. Path planning has been used on multiple thousand acres in different regions of North America, Europe, and South America, covering a variety of crops and crop production types.

For which tasks is path planning generally used in agriculture, in your view?

Path planning tech allows farmers to optimize path plans in terms of coverage, time, distance, or operational speed. This is applicable to the full crop cycle and any task performed by farm machinery, from land preparation to planting, fertilizer application, and pesticide/herbicide spraying to harvesting and mowing.

What are the main benefits of path planning technology, and why should a farmer invest in it?

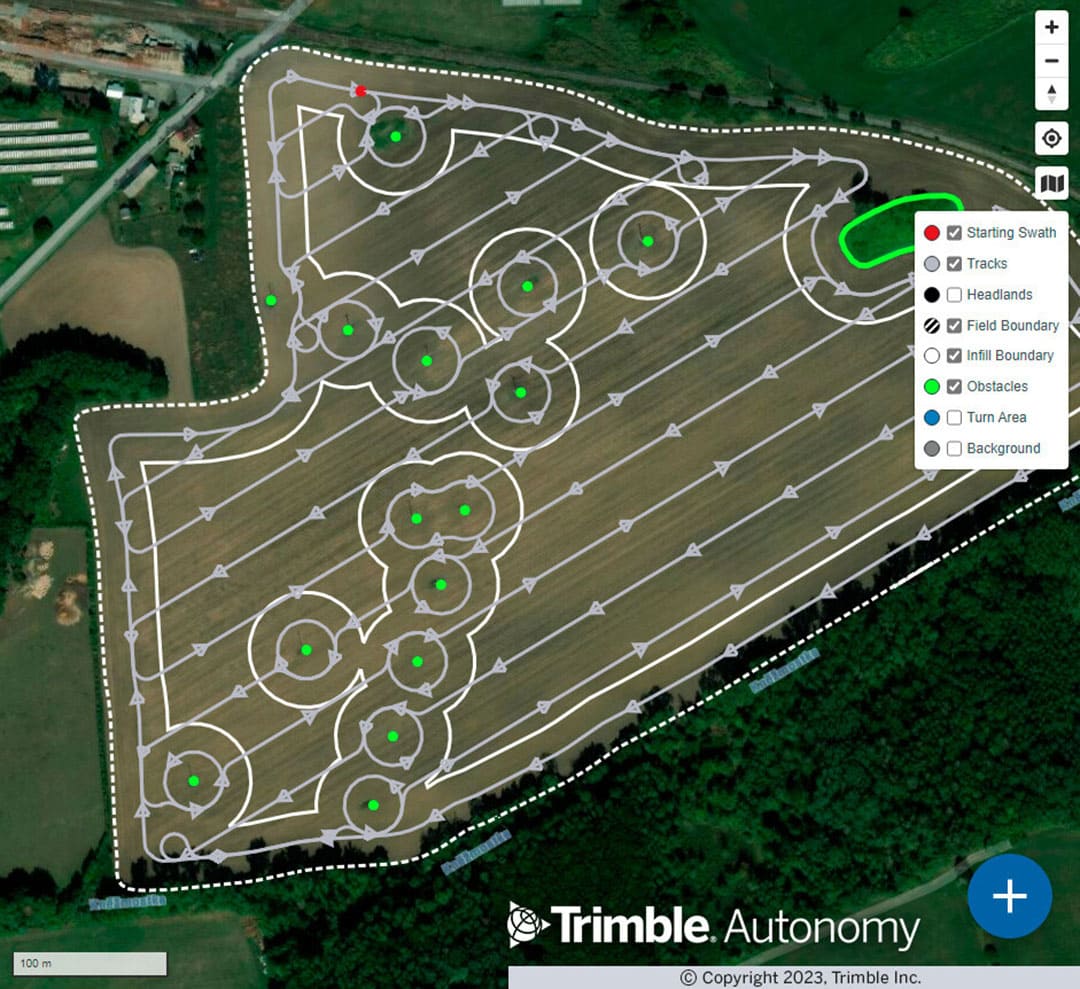

Automated and intelligent path planning technology helps to find the best coverage path so that costs of various field operations can be minimized. During peak season, farmers are confronted with the need to make many critical decisions with little time to think, as conditions can change quickly and unpredictably. This tool enables farmers and farm operations to plan the field operations well in advance, during the off-season, taking into account machine types and field environment, including obstacles.

Path planning technology empowers users to move away from a simple point-to-point navigation

This enhanced path planning technology is a tool for full field planning. Today’s precision agriculture has minimized inline overlap based on a simple point-to-point navigation with AB lines. Path planning technology empowers users to move away from a simple point-to-point navigation towards full field planning with coverage trajectory that truly support controlled traffic farming (CTF) and consistent execution on the field independent of the drivers’ field knowledge.

When does it make sense to invest in it – how many acres do you need to work in order to get a good ROI? Are there specific crops for which the technology makes extra sense to invest in?

The use of a full field plan also increases safety and reduces wear and tear on the machines. Accidents and machine damages caused by operator fatigue or during low visibility hours, such as nighttime or low standing sun, are avoided as the full field plan includes the path around or along obstacles and exclusion zones. In addition, the trajectories support speed profiling and speed control of the machines to guarantee a consistent and safe operation. Particularly in broad acre, it reduced time spent, inputs used, and energy requirements in the reduced emissions, too.

Can you give an idea – step by step – how Trimble’s new path planning tech works? If I’m a farmer, how do I start working with it in the field? What are the steps?

The planner will require certain field and machine parameters that are part of the farmer’s existing Trimble account. If the farmer is connecting via a third-party OEM platform, the data will be provided from the integrator’s database or be manually entered.

For Trimble users, they will be guided through a simple UI.

- Select a Field boundary

- Select a Vehicle and Implement

- Select an execution direction (e.g. AB line)

- Select an execution strategy

- Select potential obstacles or exclusion zones in the field

- Set your application and turn speeds

- Select your routing and execution strategy (e.g. start- and end-points, Headland direction and first, last or skip,…)

- Calculate and preview trajectory

- Send it to the machine and execute

Why did you choose to go for a ‘brand-independent’ solution, rather than sell a complete Trimble system?

Farmers want technology that can work seamlessly with multiple machine makes and types in their fleet. Trimble products and solutions have been available across a wide range of brands for decades. In line with that philosophy, we have extended our brand-agnostic approach to this new technology. Path planning will also be available via the Trimble Connected Farm, enabling farmers to utilize the existing farm and machinery information they have to create and update plans within minutes and send it directly to the machine. The operator is now empowered to execute this task from a defined start to endpoint.

How easy (or difficult) is it to get access to manufacturers’ systems, in order to integrate the Trimble system in – for instance – a John Deere of CNHi system? Don’t manufacturers want to protect their system, and have farmers buy their products instead of Trimble’s?

Path planning does not require brand-specific inputs. It is using today’s available field information such as boundaries, areas, points, or AB lines and machine parameters that are used by Trimble Autopilot Systems. In addition, the industry ISOBUS standard of TIM enables users to take advantage of speed control functionality on machines as well.

Text continues below picture

How is warranty arranged between Trimble and manufacturers in which your system is integrated? When technical issues arise, where do I go as a farmer?

The service is offered for inferential applications and levels of integration. Based on the level of integration support, service level agreements are established between the integrator and Trimble. Farmers will have a single point of contact that is providing them the path planning capability.

What are the purchase costs of Trimble Path Planning tech and what’s the ROI?

Depending on the farm location, practice, and mechanization, pricing and ROI will vary. In addition to the precision farming savings, path planning technology also reduces the supporting time of operators, reduces crop damage due to poor execution strategies or operator errors and maximizes field utilization, speed profiling, and speed control of the machines to ensure a consistent, safe operation and reduce wear and tear on the equipment.

What’s the next step towards autonomy? Will Trimble offer systems that make existing tractors fully autonomous? When?

Agricultural environments are very diverse and constantly changing. The path planning technology, in combination with speed control, enables the user to automate the full field execution more consistently and precisely than ever before, regardless of the operator’s skill or experience. The next step to full Autonomy will be to remove the operator from the actual machine to supervise the execution. The final step is the ability to operate multiple machines from a remote location. To achieve these targets, it requires a joined effort from the technology industry, legislative bodies, and the farming community. It also requires advancements in sensor technologies, full workflow automation, and legal frameworks to be able to operate fully autonomous machines in agriculture.