Turn your boom sprayer into a spot sprayer

Spot spraying is a popular topic. When thinking of spot sprayers, one often envisions a covered sprayer that applies chemicals in sections of just a few centimeters. Carbon Bee has developed a retrofit kit that can be mounted on an (existing) boom sprayer, enabling precise application of chemicals even with wide machines.

The French manufacturer Carbon Bee has designed the SmartStriker X, a camera retrofit kit that can be installed plug-and-play. The system is compatible with both new and existing boom sprayers and allows for highly precise spraying. Specifically, it operates with theoretical sections of at least 25 centimeters in width.

The manufacturer has been selling this camera technology for some time, previously through spray technology manufacturer BBLeap and now via mechanisation company Hogervorst in Noordwijkerhout, South Holland.

AI and human influence

The Carbon Bee camera housing contains a built-in 3D and RGB camera. This so-called Sensor X feels lightweight and compact. Both cameras have a field of view of 3 meters in width and 3 meters ahead.

For spot spraying, the 3D camera continuously generates a 3D map, which is sent to a central computer. The software analyses this 3D model and determines whether the detected plant is a weed that needs to be sprayed. This process is based on a complex AI algorithm combined with human input. The nozzles then open at the correct moment or remain closed. Communication is handled directly via internet cables rather than through the Isobus. Since the Isobus already carries a large amount of traffic, it could slow down the required processing speed. By directly linking the camera, controller, and spray nozzles, the system can accurately spray at speeds of up to 25 km/h. While this is unlikely to be seen in the Netherlands, it is not uncommon in countries like Australia.

Read more below the photos

The information from the Sensor X camera is transmitted directly to the controller via a data cable. The camera looks 3 meters ahead, ensuring that at a maximum speed of 25 km/h, the system has enough time to identify plants, make a decision, and open the correct nozzles to hit the target.

The information from the Sensor X camera is transmitted directly to the controller via a data cable. The camera looks 3 meters ahead, ensuring that at a maximum speed of 25 km/h, the system has enough time to identify plants, make a decision, and open the correct nozzles to hit the target.Collaborating to improve the system

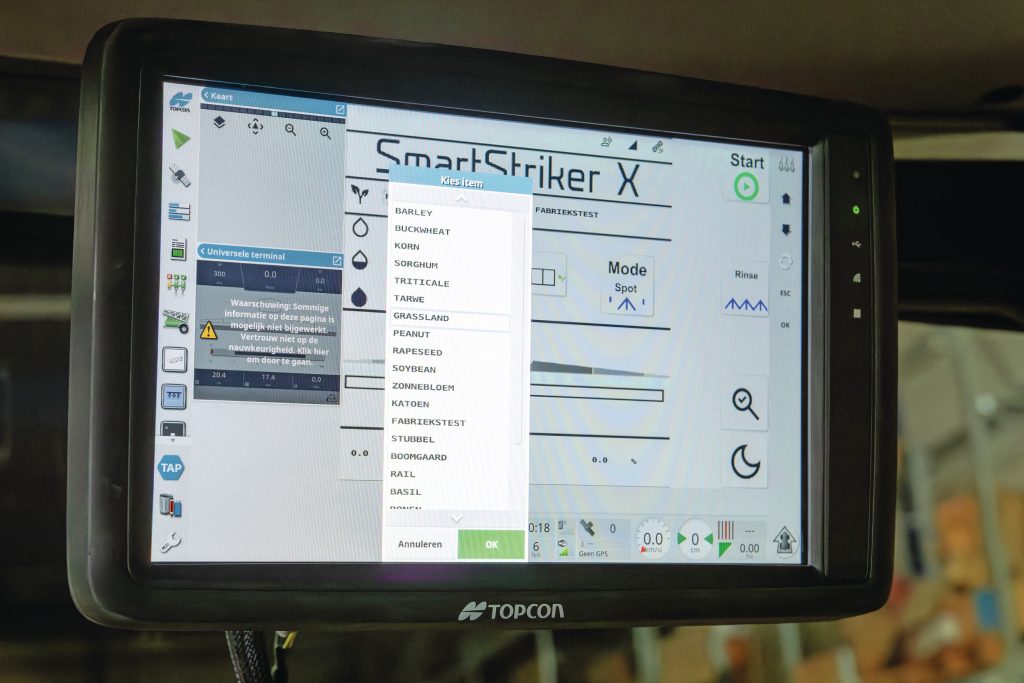

As a user, you contribute to the accuracy of the software by sharing data with other Carbon Bee system owners. An onboard eSIM (electronic SIM card) connects to the manufacturer at no extra cost. Through this wireless connection, data is shared, and updates are installed. Minor updates occur in the background. When starting the sprayer, the Isobus terminal may show a newly added crop that was unavailable the previous day. There are no extra licensing costs. Larger updates requiring more data than the eSIM can handle are installed on-site by Hogervorst.

The system already enables spot spraying using electric nozzles and/or section control with a 50 cm nozzle spacing. The cameras detect plants and control the opening or closing of the nozzles or sections accordingly. If using a 25 cm nozzle spacing, the theoretical spray zones are naturally reduced to 25 cm wide.

When combined with a suitable Pulse-Width Modulation (PWM) pulsing nozzle system, the precision is further enhanced. The rapid opening and closing of the nozzles shortens the spray zones in the lengthwise direction, making the ‘spots’ even smaller.

Beyond spot spraying

When paired with the right PWM system, the Carbon Bee can also perform dual-dose spraying. This allows for the application of a low herbicide dose across the entire field for small emerging weeds while simultaneously giving larger plants a full dose. This reduces chemical usage without underdosing stronger weeds, which could lead to resistance and continued growth.

Additionally, the system supports modulation. The RGB camera detects plant biomass and color, ensuring an even distribution of chemicals based on biomass density. For example, smaller plants can receive extra fertilizer, or the dosage of a fungicide or pesticide can be adjusted according to plant mass. This further reduces chemical use and lowers the risk of resistance, in theory.

Starting at € 2,800 per meter

The Carbon Bee camera system costs €2,800 per meter, including installation and support. For a 39-meter boom sprayer, this totals over €100,000. If the sprayer is not yet equipped with PWM, an additional €2,000 per meter must be added, plus a €10,000 starting price for an alternative spray computer recommended by Hogervorst. The system can be used with all working widths, though a stable boom is a requirement.

Despite the high investment, Hogervorst is optimistic, claiming that an arable farm of approximately 200 hectares can recoup the cost within one to two years through reduced chemical usage and increased crop yields. While the company states that chemical reduction often significantly exceeds 50%, it maintains a 50% estimate when advising customers. Experienced farmers know that not all chemicals can be spot sprayed or reduced, but when applicable to expensive chemicals, the savings can be substantial. Additionally, with less growth inhibition, yields per hectare should theoretically increase.

Plug-and-play, but not simpler

However, operators must still estimate the required chemical volume in advance. When modulating, it is essential to understand why certain field areas are underperforming. If soil compaction is the issue, applying additional nitrogen may not be the best solution. Proper preparation is necessary.

Spraying itself must also be done with care. The cameras are not designed to handle swaying, unstable booms. Overall, this is an expensive system with potential, especially as more crop protection products become restricted. However, it is important to be realistic: this system does not simply work ‘effortlessly’.