Lechler showcases Closed Transfer System at DLG Feldtage

Lechler presented a prototype of a closed transfer system (CTS) for crop protection products at the DLG Feldtage 2024 in Germany. The manufacturer also introduced a series of 20 and 30-degree nozzles. The 20-degree nozzle is mainly intended for spot spray applications. The 30-degree nozzle, which will be available first, is designed for row spraying.

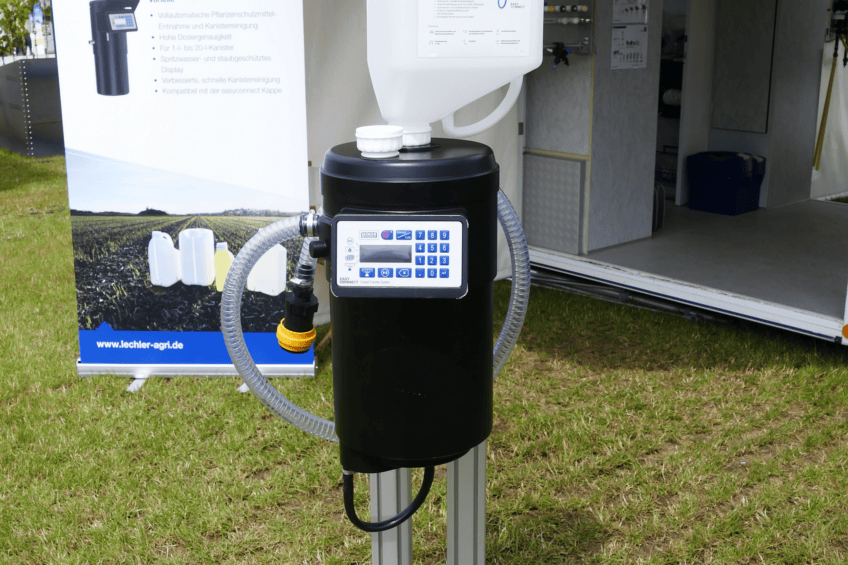

To empty and clean a container without dripping or spilling, various manufacturers have developed a CTS. To operate with these systems, they will increasingly equip containers with specially developed easyconnect caps. Lechler’s proposed CTS closely resembles that of the Israeli Tefen, imported by Homburg: it is fully electronic. The user simply inputs the amount of product to be extracted from the jerrycan, and the device does its work, including cleaning.

Read also: Closed transfer closing in fast

Memory feature

Lechler’s variant operates with a memory feature. For instance, if 18 liters of product are needed from 5-liter jerrycans, the CTS system remembers that only 3 liters need to be extracted from the third jerrycan. The displayed model from Lechler is still a prototype. The smallest amount that the Lechler Coupler (LeC), as the system is called, can dispense is 200 milliliters. In the final version, this might be reduced to 150 milliliters. The counterpart Tefen AccuRite previously had 500 milliliters as the smallest amount, but it can now also dispense from 150 milliliters.

New nozzles

Next year, Lechler can deliver a new series of 30-degree nozzles for row spraying. The series will be named ARE30. According to Lechler, it has a 90 percent drift reduction and comes in sizes ranging from 0.067 to 0.3 in terms of flow rate. As LS20, there is currently a prototype series of 20-degree nozzles primarily intended for spot spray applications. This series will range from 0.05 to 0.3. These are extremely fine nozzles that require very good filtering of the spray liquid.

Join 17,000+ subscribers

Subscribe to our newsletter to stay updated about all the need-to-know content in the agricultural sector, two times a week.