New technology to help save on fertiliser costs

Granular fertiliser prices were and are sky rocketing. How can spreaders and other applicators help save on fertiliser costs by putting the granules exactly where they belong?

While a year ago, European farmers were postponing purchases of fertilisers in anticipation of gas and thus granular fertiliser prices to come down, the tides have now turned completely. Gas prices have gone down a bit, but fertiliser prices remain at a very high level. Calcium Ammonium Nitrate and Potassium fertiliser prices are currently just below € 900 per ton. Not in the least because of scaled down production capacities at fertiliser producers and lower or even no stock at traders.

Save on fertiliser costs with modern spreaders and applicators

It currently results in a sort of fear of missing out and rapidly increasing presales of especially Calcium Ammonium Nitrate and Urea fertilisers. Once the product is secured, modern spreaders and applicators can help save on fertiliser costs by putting the granules exactly where they belong.

Below are some of the latest developments showcased at the recent SIMA exhibition in Paris, France.

Text continues below image

Kuhn Aero 32.1 pneumatic spreader

Kuhn used the SIMA to launch its Aero 32.1 pneumatic spreader with working widths of 27, 28 or 30 meters, 4 metering units and 24 diffusers. The hydraulically driven metering units enable 4 different application rates across the boom. The spreader in Kuhn livery is the ‘French version’ of the Rauch Aero 32.1. Rauch reintroduced the Aero in 2019 after an absence of 13 years because of the renewed interest and need for precise and variable rate application of granular fertiliser. It has gone on sale this Autumn with working widths of 27, 28 and 30 meters. Booms with smaller working widths are to be introduced as well.

Text continues below image

Fertiliser application with a pneumatic fertiliser spreader is less sensitive to wind influence compared to applying it with a disc spreader. Boom height sensors on the Aero make sure the boom remains stable and at the correct height. Its hopper (with extensions) can hold up to 3.200 litres of fertiliser.

Text continues below image

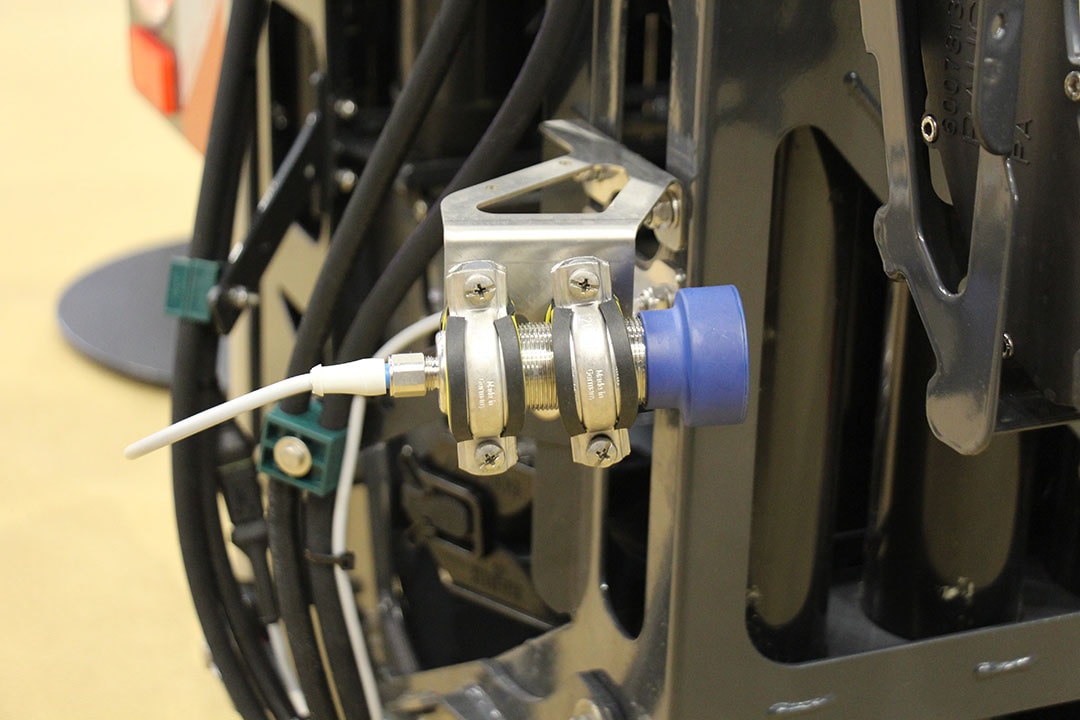

Hydraulic disc drive at Maschio

Maschio Gaspardo brought its Primo EWH Isotronic fertiliser spreader with hydraulic disc drive to Paris. While the Primo E/EW weigh cell spreader with PTO driven discs provides 8 sections across the working width, the EWH version offers a maximum of 32 sections. Maschio says the hydraulic version is also capable of two different doses for each spreading disc if application maps require such. Maschio also presented a new central border limiting device to prevent granules from flying over the field border into sensitive areas like watercourses and residential areas. The Primo EWH offers working widths of 12 to 36 metres and hopper capacities of 1.270 to 4.450 litres.

Text continues below image

Sulky speed control

While not entirely new, Sulky introduced its Speed Control technology that changes the drop off point of the fertiliser onto the spreading discs depending on the driving speed. It also uses this system to spread site-specific with sections. According to the manufacturer, the influence of the wind on the spreading pattern increases the faster you drive leading to the fact that fertiliser granules that are to be spread farthest away to the sides, fly less far at higher driving speeds. As driving speeds during applying fertiliser nowadays go up to 20 and sometimes even 30 km/h, the wind influence becomes more apparent.

Text continues below image

With Speed Control, the fertiliser granules are fed closer to the centre of the spreading discs when the driving speed increases. The vanes can now exert more force to the granules in order to throw, spread them further away. By doing this, the ‘narrow working width’, resulting from an increase in wind, is compensated automatically by ‘widening’ the spreading pattern. Sulky was awarded a silver innovation medal for its Speed Control technology by the SIMA organisation last year. Speed Control is currently available on the X40+ Econov and X50+ Econov models.