Controlled Row Farming: Making a profit while promoting biodiversity

German company Amazone is testing new technologies in Controlled Row Farming (CRF) to generate good yields and profits together with a maximum contribution to biodiversity.

Both goals should be met but ideally also support each other. “Farmers should have a toolbox, with different options”, says Stefan Kiefer, Head of Innovation in Crop Production at Amazone.

The manufacturer of agricultural and ground care machinery is introducing the new variants of the arable farming system in collaboration with Agravis Raiffeisen AG and Schmotzer Hacktechnik, using long-term field trials. Each crop cultivation measure takes place in relation to a fixed row, at a row spacing of 50 cm. The spacious trials area is located on test centre ‘Gut Wambergen’ (10 hectares) in the direct vicinity of Amazone in Hasbergen-Gaste (Germany).

Agricultural experts and design engineers at Amazone and Schmotzer will develop and test new technologies and tools in the trials. Arable farming advisers at Agravis will provide their expertise to help select the right varieties and inputs.

“We have been working on new arable methods for many years”, Mr Kiefer says. “We started with reduced tillage and have had trials in Germany, but also in the Netherlands, France and Russia over the years. We have had many discussions with growers more recently and understood that we had to work on trials, that also include precision equipment; row depended tools and input placement.”

Text continues below image

Big interest in hoeing equipment

Mr Kiefer says that only a small group of farmers is currently using controlled row farming. “But growers are thinking about the future. What is my next plan as a farmer? How can I integrate hoeing in my conventional farming business? We notice there is a big interest in hoeing equipment at the moment.”

The agricultural experts of the companies are testing different technologies and tools. Mr Kiefer: “We are finding out what tools are needed to put fertiliser in the right place. And how we perhaps can place the crop for undersowing better. Nowadays cover crops are planted with a professional seeder. That gives farmers a better weed control, a good use of sunlight and organic material in their soil. That was not the case 10 years ago. Things are changing.”

Companion plants

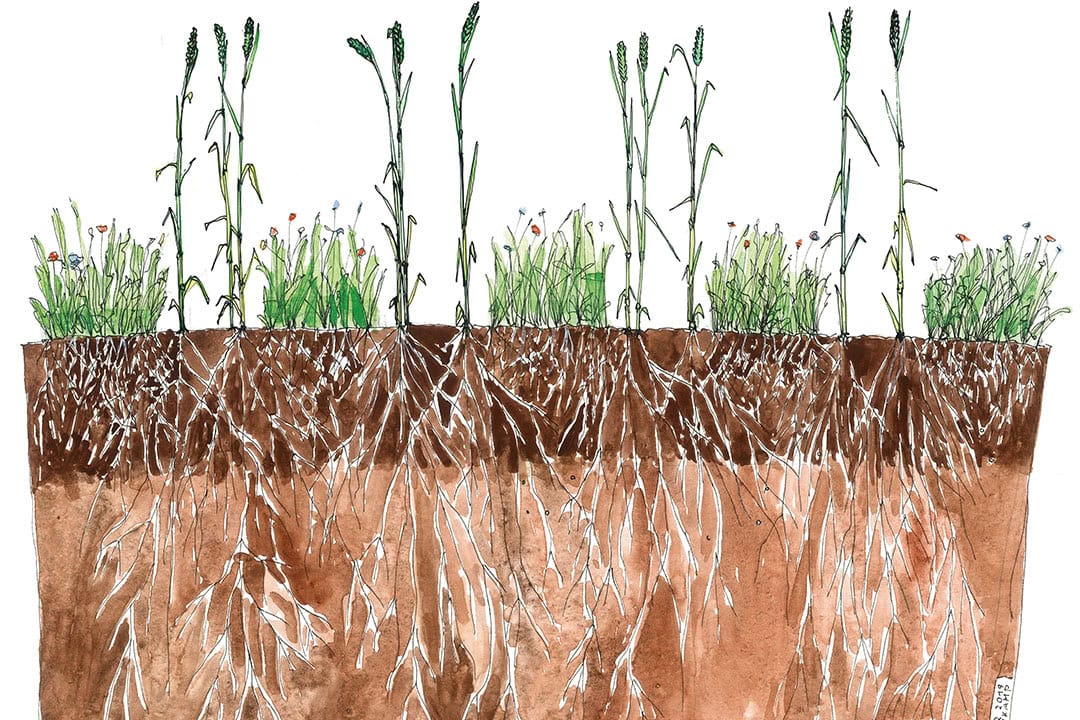

Mr Kiefer explains that hoeing technology is used for mechanical weed control in combination with row-specific plant protection, targeted fertiliser application and sowing of companion plants between the rows.

These companion plants – without direct contact with fertiliser and plant protection agents – make a positive contribution to the phytosanitary support of the main crop as well as to soil fertility and biodiversity. Depending on the crop and weather conditions, the companion plants are actively managed, to ensure the crop can be harvested.

“We developed a concept for the trials, where we are looking at row dependant fertilising and spraying”, Mr Kiefer says. “Farmers in Europe are using a certain row width not only for the crop that is planted, but also for management purposes. If you look at organic farmers, you often see that they are using different row width often in combination with different hoeing technologies on the farm. This is quite expensive.”

Text continues below image

Good practices

“In Europe you can see a lot of farmers that use oil seed rape in crop rotation for the winter crop”, Mr Kiefer explains. “In the last 20 years growers have been mainly using standard seeders. But recently the rows have been wider because of resistance problems and ecological pressure. As a solution, farmers have been putting corn in the crop rotation, adding it to the traditional crops of winter wheat, winter barley and rape. They invest in a 50 cm row spacing precision air planter and use this planter twice a year. But they can also do their hoeing or use their large boom sprayer. Good practices like this have led us to the trials.”

Sowing is normally carried out in combination with row-oriented fertilisation. Plant protection is primarily applied row-specifically by means of band application on the row and via Dropleg systems at later growth stages. Each pass is carried out with high-precision track guidance via RTK-GPS and camera control.

Two different intensities are compared in the trials: One variant puts the emphasis on the maximum yield with limited competition from companion plants. The second variant focuses on biodiversity with reduced intensity of fertiliser and plant protection measures. The two CRF variants are compared with two intensity levels of the usual soil management in the region.

Text continues below image

More sustainable agriculture and biodiversity

In Europe, especially in countries like Germany and France, agriculture is moving towards more sustainable agriculture and biodiversity, Mr Kiefer emphasises. “We bring this into the field. With CRF we bring flowering plants – biodiversity – in the whole field. We bring in companion plants and control these plants with mechanical tools.”

All crop plants are grown at a row spacing of 50 cm in the CRF concept, whereby cereals are sown in double rows. Depending on the crop rotation, the rows can be moved 25 cm the following year, so that the main crop can make use of the pre-fertilisation effects of the underseeding sown the year before.

“And undersowing can suppress weeds as well. We like to be flexible”, Mr Kiefer says. “Creating the best undersowing conditions are a good example of what we are doing. Farmers should have a toolbox, with different options.”

A six-year crop rotation with cereals and corn is typical for the region around Amazone’s test centre ‘Gut Wambergen’. It consists of the establishment of rape and pulses as well as intensive catch crop cultivation in accordance with the principles of sustainability. A good basis for an intense exchange of experience with the practitioners in the trials will be established with the simultaneous cultivation of four crops in four variants on one area.

“This year we will establish beans in 50 cm rows but we can also establish beans in a twin-row and use a standard seeder”, Mr Kiefer points out. “If the farmer in the trial says he wants to have more plants per hectare, we change to twin-rows of and he can get a higher yield per hectare. These rows are 12.5 cm and allow us to place liquid fertiliser in the rows for example. We have two open rows for seeding and two closed rows for the companion plants.”

Weed control is carried out by hoeing and sowing companion plants between the rows. By using these plants in the open spaces between the main crops, it is also possible to reduce water evaporation and erosion of the land.

Text continues below image

Less fertiliser, herbicides and fungicides

“We use a machine with a width of 6 metres”, Mr Kiefer explains. “In this machine we have a band herbicide sprayer integrated in the hoeing equipment. We also have the feeding unit there to establish the companion plants. This year we will start with row dependent liquid fertiliser. We are also considering adding a unit for granules. We will match everything to the crop rotation.”

A reduction of the use of fertiliser, herbicides and fungicides is also part of the trials. “At the moment it is looking good”, Mr Kiefer emphasises. “Our methods are not more expensive than conventional farming methods. And the prices of fertiliser and herbicides are rising, so we could have even better results soon.”

Autonomous machines

Amazone is currently considering using autonomous machines in the trials. “Farmers often drive their 6-metre machine with hoeing or spraying equipment to fast over the field, to compensate for their lack of time”, Mr Kiefer says. “This causes problems. The control of the machine is getting stressed. The fuel consumption is higher and the accuracy is worsening.”

A solution for this problem could be the use of a simple 3-metres wide autonomous robot. “We could use the Dutch Agxeed robot for example”, he says. “A robot like this drives with a speed of 8 km per hour and this is very accurate. It can do the job in three or four hours and then the farmer can put it to use on the next field.” Mr Kiefer says that labour costs are the biggest expense in row farming and the use of autonomous robots would save on these costs.

We can show a wide range of technologies to farmers and they can choose what is useful for them

The trials started in 2020 will continue for at least 10 years. The results and finding are regularly presented to farmers during field demonstrations. “We can try out a wide range of technologies here”, Mr Kiefer says. “We can then show them to farmers and they can choose what is useful for them.”

“Starting in May this year growers from different countries can have a look at our trials for the first time. A lot of experts have already told us that the trials are very interesting. We are convinced that digital farming – for example spot spraying – is not the only solution for the future.”

Amazone can support growers – also in other countries – that are interested in using controlled row farming methods on their farm.

Text continues below image